Amazon Shortages & Chargebacks: Suppliers tips & tricks for managing these fines

By Cleveland Admin93% of brands receive supply chain-related chargebacks from Amazon

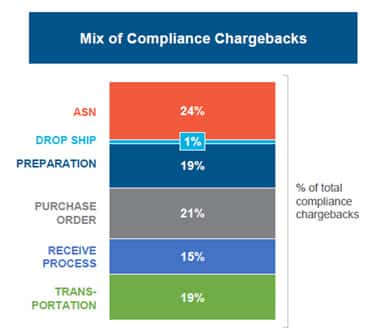

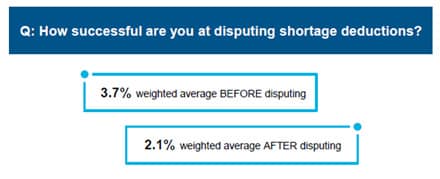

In our benchmarking data we found that nearly all brands receive supply chain-related chargebacks from Amazon, and 90% report receiving shortage deductions that are believed to be incorrect. Benchmarking data from Fall 2020 suggests these fines are typically in the low-single-digits range as a percentage of sales, although broader, more recent research indicates chargebacks and shortages have increased dramatically in recent months, perhaps due to fulfillment center capacity constraints driving greater inaccuracies in the receiving process. Our benchmarking data suggests the most prevalent type of compliance chargeback is Advanced Shipping Notice (ASN)-related at 24% of total chargebacks, followed closely by purchase orders (21%), transportation (19%) and preparation (19%).

Below details one best practice for successful claim disputing and one best practice for avoiding these fines in the first place.

Claim escalation can drive successful disputing

When disputing shortage deductions, one tip is to resubmit multiple dispute claims as a single batch in order for the submission to get escalated within Amazon. Some brands have found that when the total sum of the claim exceeds $200,000, the claim is escalated which results in Amazon performing a full audit on every line item. This can lead to brands receiving more money back when the fines are incorrect, as well as put greater responsibility on Amazon to figure out flaws in their in-bound receiving processes to prevent future issues.

Consider alternative shipping methods to prevent future fines

Brands’ inventory is more or less susceptible to shortage deductions and chargebacks based on how it is shipped to Amazon and how Amazon receives the inventory into its fulfillment centers. Some of Amazon’s hot programs with suppliers right now include the Full Truckload and Pallet Ordering programs. Both programs typically have the effect of consolidating volume into a fewer number of purchase orders that are easier on the Amazon team to receive, in essence reducing the risk of shortages. Pallet Ordering can also help to avoid some of Amazon’s labelling requirements on mixed pallet orders (or otherwise the related non-compliant chargeback).

Alternative programs include Amazon’s Vendor Flex where an Amazon team operates a “mini fulfillment center” within the brand’s distribution center to ship Amazon orders, or, Direct Fulfillment / drop ship where the brand fulfills the Amazon orders themselves. Both of those shipping methods completely bypass the Amazon FC network and therefore the risk of shortages or in-bound chargebacks.